Steam trap TBU4 / TBU4B/ TBU4B-C

- SCCV system

- Stainless steel

- Suitable for condensate recovery

- Horizontal installation

- Vertical installation

-

Reduces scale deposits

Complete redesign of all internal components.

・33 % higher bimetallic valve lift

・2.2 x higher spring opening force

・Enlarged valve seat, flow channel and cross-section

* Compared to previous Miyawaki products -

Outstanding durability

The MIYAWAKI SCCV system (Self Closing and Centering Valve) is characterized by a significantly longer service life thanks to the reduced closing forces.

The freely rotating valve always sits optimally in the valve guide, even under the extreme conditions that prevail in high-pressure applications, as it is centered and guided by the condensate flow. This design significantly reduces stress and therefore wear on the valve components.

-

Energy savings

Controlling the temperature of the discharged condensate ensures significant energy savings. In particular, if the sensible heat of the condensate can be used for heating in applications, the trap significantly reduces steam consumption.

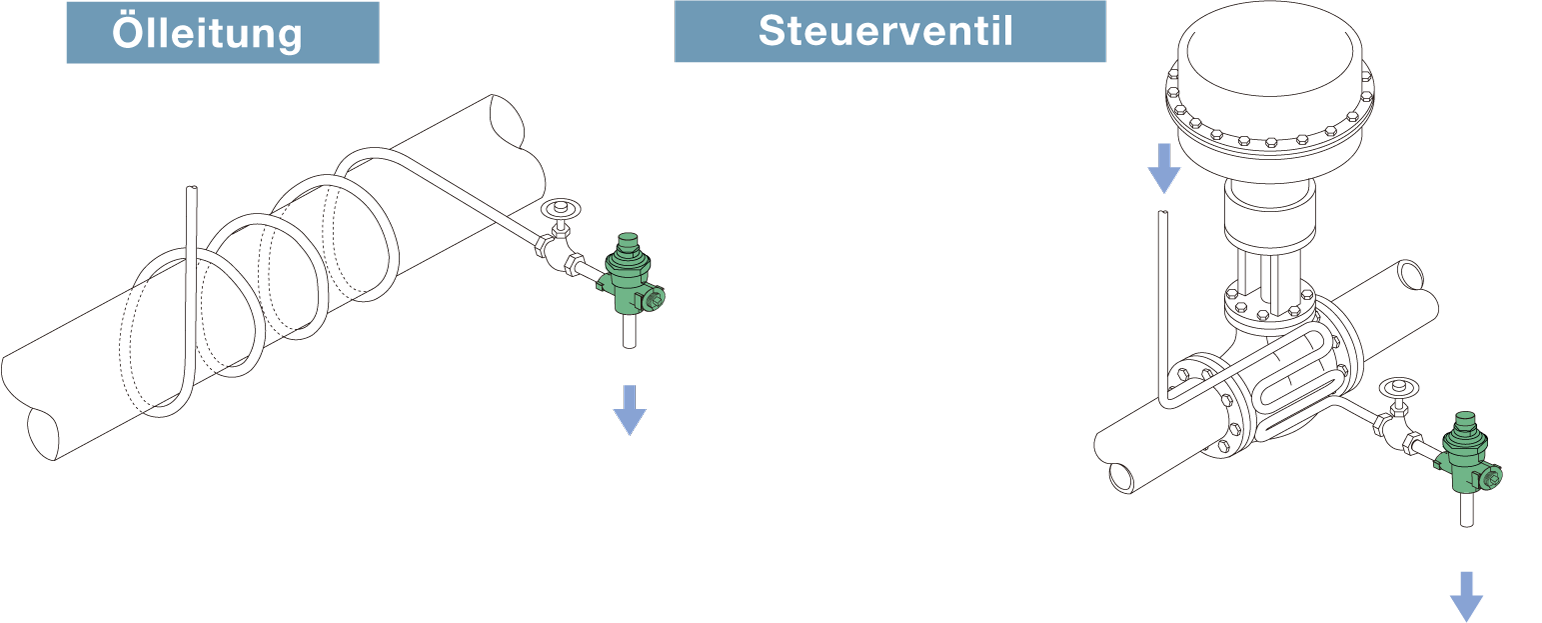

Typical applications

Suitable for trace heating in industrial plants.

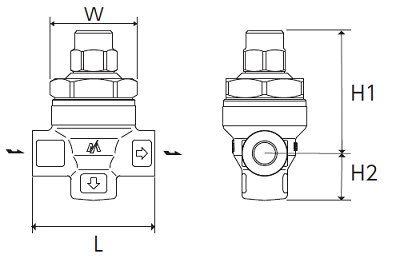

Threaded sleeve

| Nominal width | Dimensions (mm) | Weight | |||

|---|---|---|---|---|---|

| L | H1 | H2 | W | (kg) | |

| 1/4″ | 65 | 65 | 25 | 46 | 0,58 |

| 3/8″ | |||||

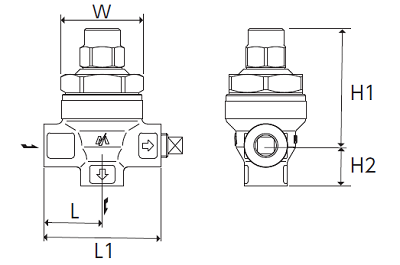

With blow-down valve

| Nominal width | Dimensions (mm) | Weight | ||||

|---|---|---|---|---|---|---|

| L | L1 | H1 | H2 | W | (kg) | |

| 1/4″ | 32.5 | 65 | 65 | 22.5 | 46 | 0,58 |

| 3/8″ | ||||||

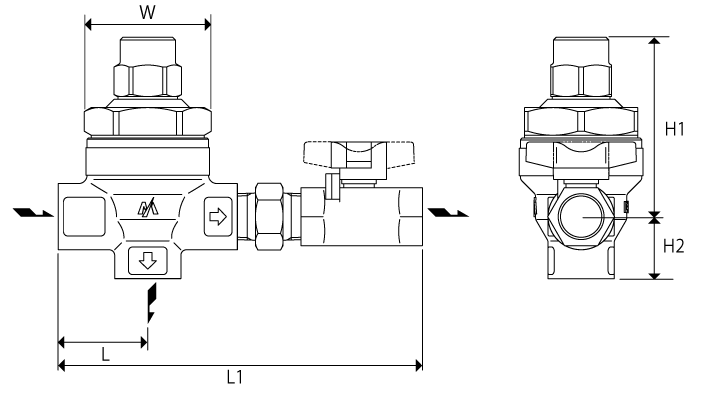

With ball valve

| Nominal width | Dimensions (mm) | Weight | ||||

|---|---|---|---|---|---|---|

| L | L1 | H1 | H2 | W | (kg) | |

| 1/4″ | 32.5 | 127 | 65 | 22.5 | 46 | 0,68 |

| 3/8″ | 132 | |||||

| Model | Connection | Max. Operating pressure (bar) | Max. Differential pressure (bar) | Max. Operating temperature (℃) | Setting range (℃) | Default setting (℃) | Housing material | |

|---|---|---|---|---|---|---|---|---|

| Type | Nominal size | |||||||

| TBU4-6 Threaded socket |

Threaded socket Rc, NPT |

1/4″ | 6*1 | 6 | 220 | 50~130 | 70 (at 5 bar) |

Stainless steel SUS F304 /A182 F304 |

| 3/8″ | ||||||||

| TBU4B-6 With blowdown valve |

1/4″ | |||||||

| 3/8″ | ||||||||

| TBU4B-6C With ball valve |

1/4″ | 6*2 | 183 | |||||

| 3/8″ | ||||||||

*1 Max. Operating pressure of 10 bar available as a special design.

*2 Max. Operating pressure of 9.8 bar available as a special design.

● The factory-set standard temperature can be changed. Please enter the operating pressure and set temperature.

● Information on adjusting the setpoint temperature can be found in the installation instructions.

● ⊿t is the difference between the temperature of a temperature control trap when the valve is first opened and the temperature of the condensate.

The temperature difference (⊿t) at the first flow of air is large and indicates that the flow rate will also increase.

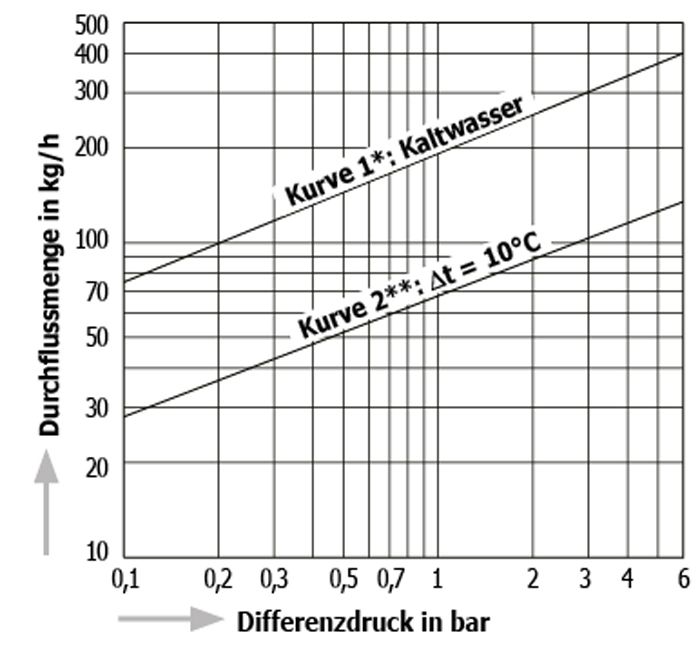

* Curve 1 shows the maximum capacity of the trap when discharging cold condensate.

** Curve 2 shows the maximum capacity of the trap when discharging hot condensate with a temperature of 10 °C below the setpoint temperature of the trap.