Steam trap TB52

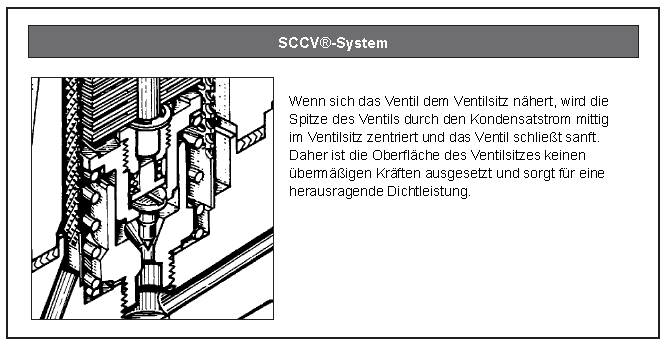

- SCCV system

- Suitable for condensate recovery

- Horizontal installation

- Vertical installation

-

Completely closed

The temperature control trap enables adjustable subcooling of the condensate. This maintains a specific condensate level in the trap. The mechanism is 100% leak-proof, which effectively prevents steam loss during operation.

-

Suitable for high pressures, high temperatures and superheated steam

-

Outstanding durability

The MIYAWAKI SCCV system (Self Closing and Centering Valve) is characterized by a significantly longer service life thanks to the reduced closing forces.

The freely rotating valve always sits optimally in the valve guide, even under the extreme conditions that prevail in high-pressure applications, as it is centered and guided by the condensate flow. This design significantly reduces stress and therefore wear on the valve components. -

Fast commissioning

Discharges the cold condensate and cold air quickly.

-

Energy savings

Controlling the temperature of the discharged condensate ensures significant energy savings.

Typical applications

Suitable for ultra-high pressure and high temperature applications such as superheated steam pipes, turbine heads and other similar applications.

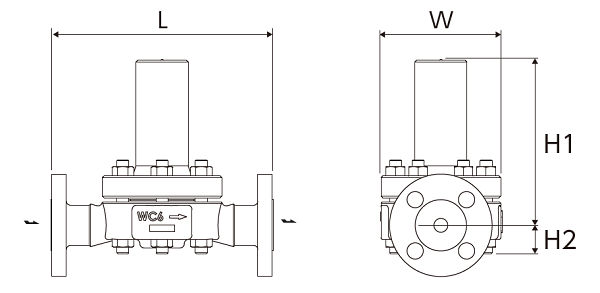

Flange

| Nominal width | Dimensions (mm) | Weight | |||

| L | H1 | H2 | W | (kg) | |

| 1/2″ | 260 | 195 | 33 | 140 | 16,0 |

| 3/4″ | 17,0 | ||||

| 1″ | 19,0 | ||||

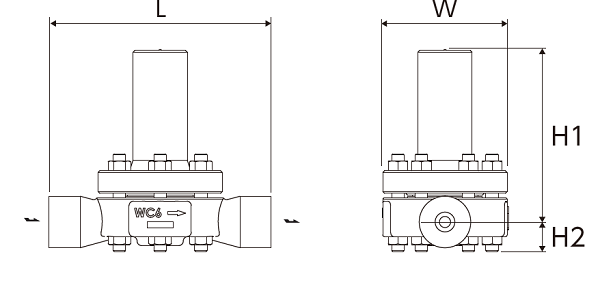

Welding socket

| Nominal width | Dimensions (mm) | Weight | |||

| L | H1 | H2 | W | (kg) | |

| 1/2″ | 250 | 195 | 33 | 140 | 13,0 |

| 3/4″ | |||||

| 1″ | |||||

| Model | Connection | Max. Operating pressure |

Max. Differential pressure |

Max. Operating temperature |

Setting range | Default setting | Housing material | |

| Type | Nominal diameter | (bar) | (bar) | (℃) | (℃) | (℃) | ||

| TBH71-80F | Flange FF,RF |

1/2″ | 80 | 80 | 470 | 100 – 260 | 210 (at 65bar) |

Cast steel WC6 |

| 3/4″ | ||||||||

| 1″ | ||||||||

| TBH71-80W | Welding socket SW |

1/2″ | ||||||

| 3/4″ | ||||||||

| 1″ | ||||||||

| TBH71-105F | Flange FF,RF |

1/2″ | 105 | 105 | 100 – 280 | 230 (at 80 bar) |

||

| 20 | ||||||||

| 25 | ||||||||

| TBH71-105W | Welding socket SW |

1/2″ | ||||||

| 3/4″ | ||||||||

| 1″ | ||||||||

* Available flange standards: ASME/JPI 600lb, 900lb, 1500lb, DIN PN63, 100, 160, JIS 30K, 40K, 63K

* Welding socket standards:ASME 2500 lb, JPI 2500 lb, JIS sch 160

● Max. permissible pressure (PMA): 118 bar (at 425 ℃)

● Max. permissible temperature (TMA): 593 ℃ (at 13 bar)

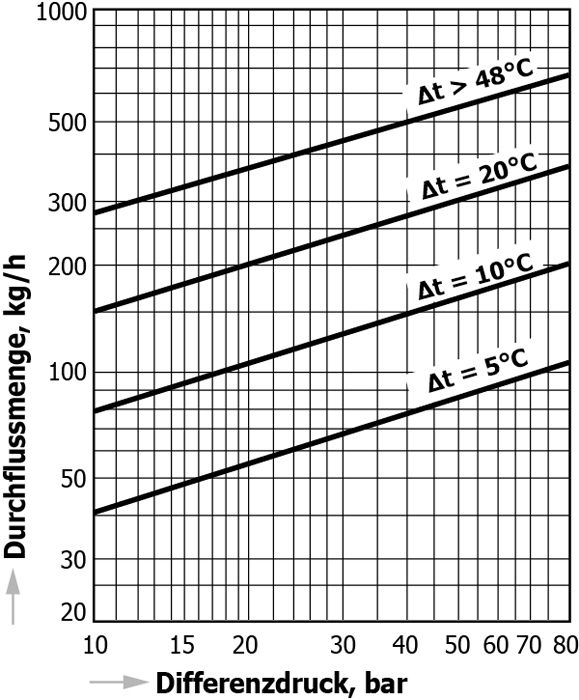

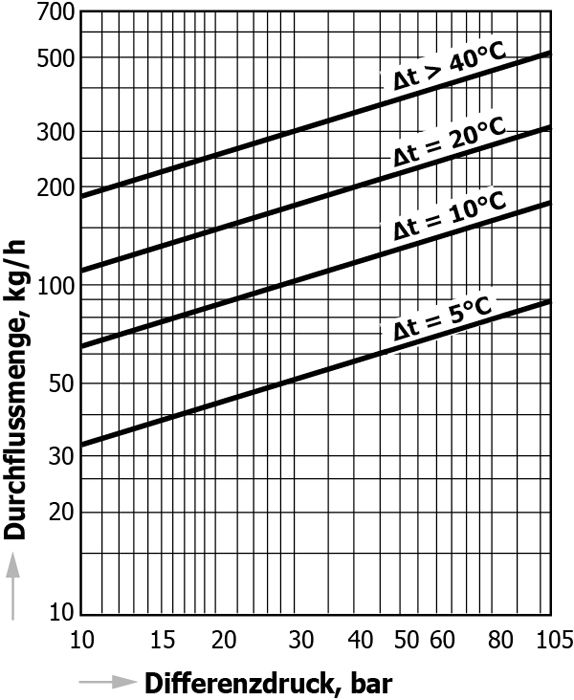

● Min. operating differential pressure (⊿PMN): 10 bar ⊿PMN is the minimum operating differential pressure between the inlet and outlet of the condensate drain.

● If there are no special instructions for the set temperature, the product is set to the above factory default setting for shipping.

The set temperature must be at least 30 ℃ lower than the saturation temperature for the vapor pressure used.

* The TBH71 housing can also be manufactured from a forged chrome-molybdenum steel alloy (A182 F22).

TBH71-80

TBH71-105

● ⊿t is the difference between the temperature of a temperature control trap when the valve is first opened and the temperature of the condensate. The temperature difference (⊿t) at the first flow of air is large and indicates that the flow rate will also increase.