Steam trap TB1N

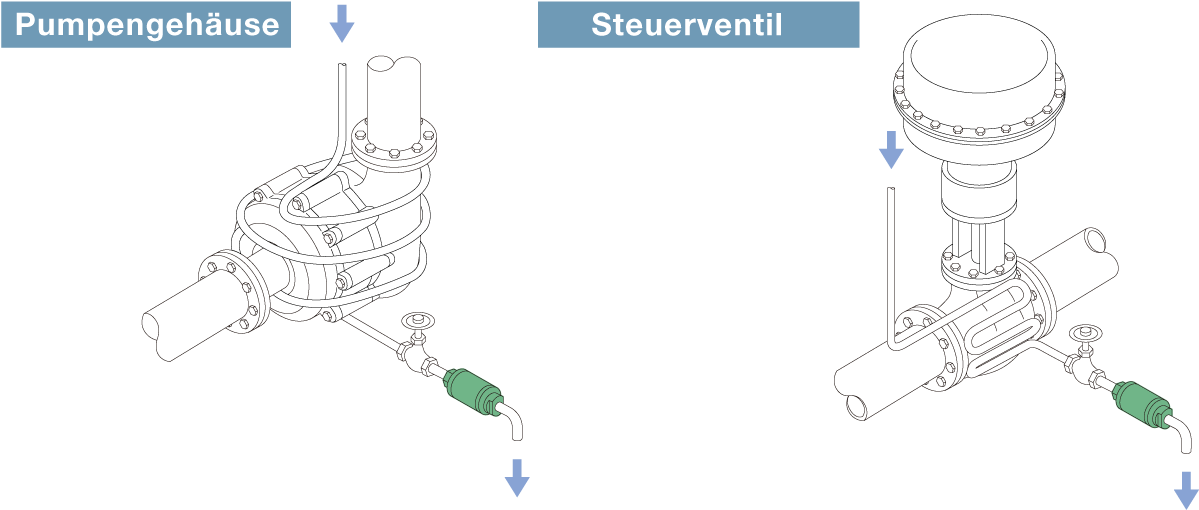

- Suitable for condensate recovery

- Horizontal installation

- Vertical installation

-

This product can be installed both horizontally and vertically.

-

Compact design

Can be installed in small spaces.

-

Works with highly sensitive bimetal disks

Precise response behavior even with small temperature fluctuations. The low weight of the arrester also reduces the load on the pipe (whether made of copper or another material) on which it is mounted.

-

Constant trace heating

The valve mechanism developed by MIYAWAKI reduces temperature fluctuations in the trace heating and ensures a uniform temperature.

-

Easy maintenance

The bimetals are arranged in groups to simplify maintenance.

Typical applications

Suitable for trace heating and systems in the oil, petrochemical, electricity, smelting, etc. industries.

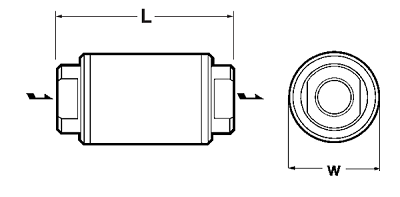

| Nominal width | Dimensions (mm) | Weight | |

| L | W | (kg) | |

| 1/4″ | 70 | 38 | 0,35 |

| 3/8″ | |||

| Model | Connection | Max. Operating pressure |

Max. Operating differential pressure |

Max. Operating temperature |

Setting range | Default setting | Housing material | |

| Type | Nominal diameter | (bar) | (bar) | (℃) | (℃) | (℃) | ||

| TB1N | Threaded socket Rc, NPT |

1/4″ | 16 | 16 | 350 | 50 – 90 | 70 (at 5 bar) |

Carbon steel S25C |

| 3/8″ | ||||||||

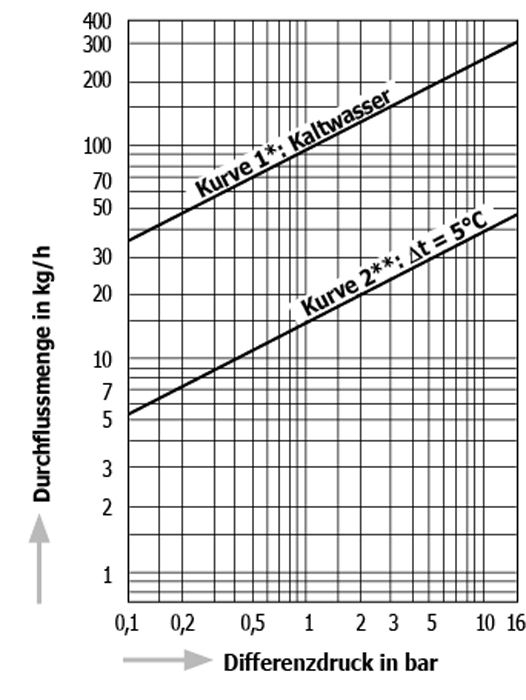

● ⊿t is the difference between the temperature of a temperature control trap when the valve is first opened and the temperature of the condensate.

The temperature difference (⊿t) at the first flow of air is large and indicates that the flow rate will also increase.

* Curve 1 shows the maximum capacity of the trap when discharging cold condensate.

** Curve 2 shows the maximum capacity of the trap when discharging hot condensate with a temperature of 5 °C below the setpoint temperature of the trap.