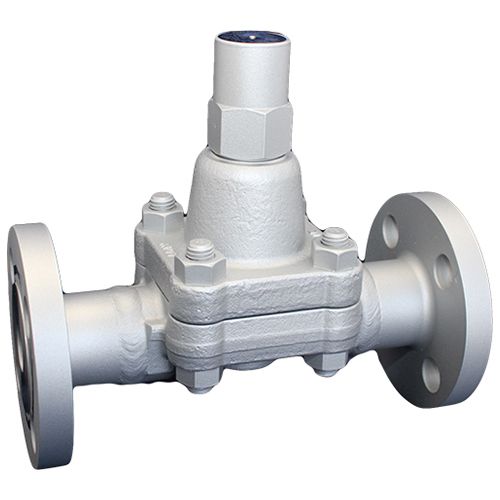

Steam trap TB52

- SCCV system

- Suitable for condensate recovery

- Horizontal installation

- Vertical installation

- Option

– Customized flange

-

Completely closed

The temperature control trap enables adjustable subcooling of the condensate. This maintains a specific condensate level in the trap. The mechanism is 100% leak-proof, which effectively prevents steam loss during operation.

-

Suitable for high pressures, high temperatures and superheated steam

-

Outstanding durability

The MIYAWAKI SCCV system (Self Closing and Centering Valve) is characterized by a significantly longer service life thanks to the reduced closing forces.

The freely rotating valve always sits optimally in the valve guide, even under the extreme conditions that prevail in high-pressure applications, as it is centered and guided by the condensate flow. This design significantly reduces stress and therefore wear on the valve components. -

Fast commissioning

Discharges the cold condensate and cold air quickly.

Also functions as a deaerator.

-

Energy savings

Controlling the temperature of the discharged condensate ensures significant energy savings.

-

Low operating noise and very low formation of flash steam

Typical applications

Suitable for steam main lines, steam tracing and other similar applications.

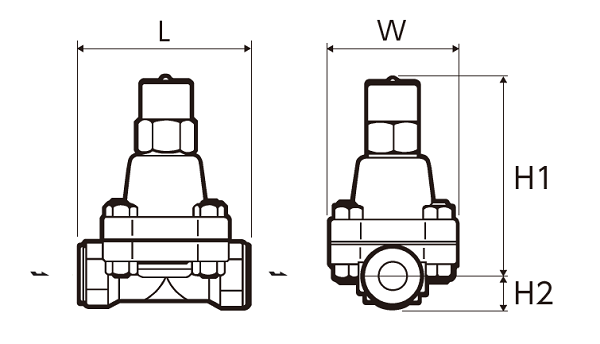

Threaded socket/welding socket

Here is the customized table based on the template you provided:

| Nominal width | Dimensions (mm) | Weight (kg) |

|||

|---|---|---|---|---|---|

| L | H1 | H2 | W | ||

| 1/2″ | |||||

| 3/4″ | 130 | 155 | 25 | 100 | 5,7 |

| 1″ | |||||

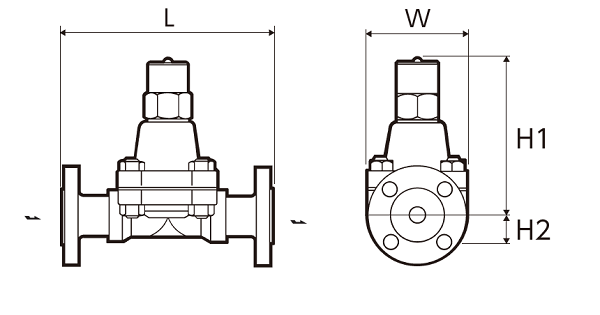

Flange

| Nominal width | Flange standards | Dimensions (mm) | Weight | ||||

| L | H1 | H2 | W | (kg) | |||

| 1/2″ | JIS (RF) |

20K | 200 | 155 | 25 | 100 | 7,3 |

| 30K | 8,4 | ||||||

| 40K | 8,7 | ||||||

| 63K | 220 | 9,6 | |||||

| ASME/JPI (RF) |

150lb | 200 | 6,7 | ||||

| 300lb | 7,2 | ||||||

| 600lb | 7,3 | ||||||

| 900lb | 220 | 9,6 | |||||

| 3/4″ | JIS (RF) |

20K | 210 | 7,7 | |||

| 30K | 8,9 | ||||||

| 40K | 9,2 | ||||||

| 63K | 230 | 11,1 | |||||

| ASME/JPI (RF) |

150lb | 210 | 7,7 | ||||

| 300lb | 8,2 | ||||||

| 600lb | 8,5 | ||||||

| 900lb | 230 | 10,9 | |||||

| 1″ | JIS (RF) |

20K | 240 | 9,2 | |||

| 30K | 10,1 | ||||||

| 40K | 10,5 | ||||||

| 63K | 12,1 | ||||||

| ASME/JPI (RF) |

150lb | 8,3 | |||||

| 300lb | 9,4 | ||||||

| 600lb | 9,6 | ||||||

| 900lb | 13,3 | ||||||

| DN15 | DIN PN63/PN100 | 210 | 155 | 25 | 100 | 9,4 | |

| DN20 | 230 | 11,4 | |||||

| DN25 | 12,1 | ||||||

* Customized dimensions on request.

| Model | Connection | Max. Operating pressure (bar) | Max. Differential pressure (bar) | Max. Operating temperature (℃) | Setting range (℃) | Default setting (℃) | Housing material | |

|---|---|---|---|---|---|---|---|---|

| Type | Nominal size | |||||||

| TB52-45 | Threaded socket Rc,NPT |

1/2″ | 45 | 45 | 475 | 100 – 220 | 180 (at 21 bar) | Chrome-molybdenum steel A182 F22 |

| 3/4″ | ||||||||

| 1″ | ||||||||

| TB52-65 | 1/2″ | 65 | 65 | 100 – 240 | 220 (at 44 bar) | |||

| 3/4″ | ||||||||

| 1″ | ||||||||

| TB52F-45 | Flange RF |

1/2″ | 45 | 45 | 100 – 220 | 180 (at 21 bar) | ||

| 3/4″ | ||||||||

| 1″ | ||||||||

| TB52F-65 | 1/2″ | 65 | 65 | 100 – 240 | 220 (at 44 bar) | |||

| 3/4″ | ||||||||

| 1″ | ||||||||

| TB52W-45 | Welding socket SW |

1/2″ | 45 | 45 | 100 – 220 | 180 (at 21 bar) | ||

| 3/4″ | ||||||||

| 1″ | ||||||||

| TB52W-65 | 1/2″ | 65 | 65 | 100 – 240 | 220 (at 44 bar) | |||

| 3/4″ | ||||||||

| 1″ | ||||||||

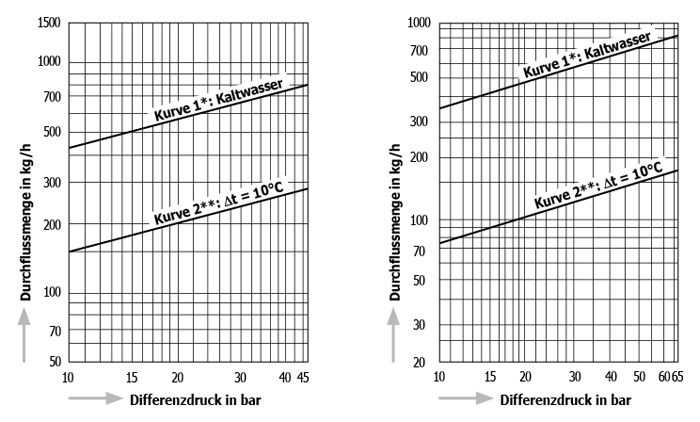

● ⊿t is the difference between the temperature of a temperature control trap when the valve is first opened and the temperature of the condensate. The temperature difference (⊿t) at the first flow of air is large and indicates that the flow rate will also increase.

* Curve 1 shows the maximum capacity of the trap when discharging cold condensate.

** Curve 2 shows the maximum capacity of the trap when discharging hot condensate with a temperature of 10 °C below the setpoint temperature of the trap.