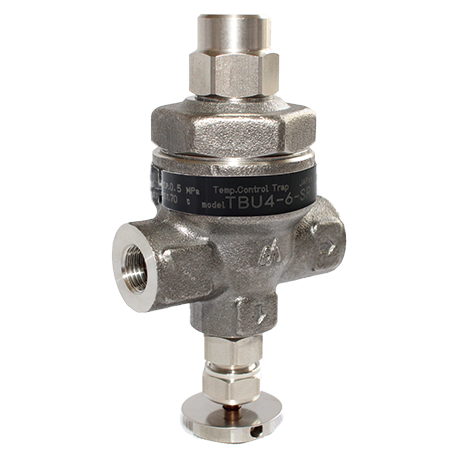

Steam trap TBU4-SR

- SCCV system

- Stainless steel

- Suitable for condensate recovery

- Horizontal installation

- Vertical installation

-

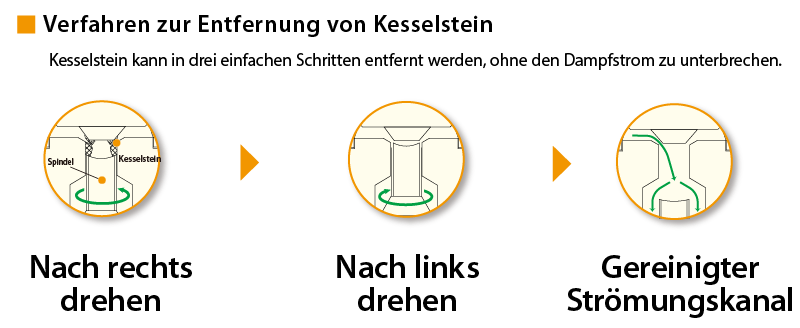

Scale can be removed 10 times faster than with conventional models.

Disassembly before cleaning is no longer necessary. Scale is removed immediately by simply turning a handle without having to interrupt the steam flow. This only takes around 3 minutes per trap.

-

Reduces scale deposits

Complete redesign of all internal components.

・33 % higher bimetallic valve lift

・2.2 x higher spring opening force

・Enlarged valve seat, flow channel and cross-section

* Compared to previous Miyawaki products

-

Preventive measures to ensure the locking function

This product enables efficient, regular removal of scale. Regular removal prevents scale from impairing the closing function.

-

Outstanding durability

SCCV system (Self Closing and Centering Valve)/This is a mechanism developed by Miyawaki to increase valve service life.

Gentle closing increases the service life.

Remove the scale by simply turning a handle!

This temperature control trap has a mechanism that allows you to remove limescale deposits in the flow channel (of the valve hole) and empty it by simply turning a handle on the underside.

Typical applications

Suitable for steam tracing lines in systems.

| Nominal width | Dimensions (mm) | Weight | |||

|---|---|---|---|---|---|

| L | H1 | H2 | W | (kg) | |

| 1/4″ | 65 | 65 | 58 | 46 | 0,62 |

| 3/8″ | |||||

| Model | Connection | Max. Operating pressure |

Max. Differential pressure |

Max. Operating temperature |

Setting range | Default setting | Housing material | |

|---|---|---|---|---|---|---|---|---|

| Type | Nominal diameter | (bar) | (bar) | (℃) | (℃) | (℃) | ||

| TBU4-6-SR | Threaded socket Rc, NPT |

1/4″ | 6* | 6 | 220 | 50 – 130 | 70 (at 5 bar) |

Stainless steel SUS F304 / A182 F304 |

| 3/8″ | ||||||||

*Can also be manufactured with a maximum operating pressure of 10 bar.

*It is possible to change the factory-set standard temperature. Please specify operating pressure and set temperature.

*Please refer to the installation instructions to find out how to adjust the set temperature.

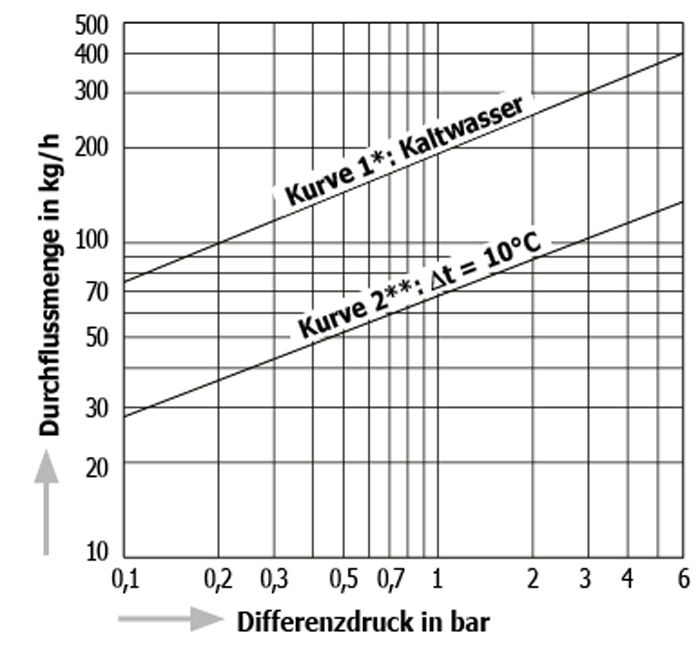

●⊿t is the difference between the temperature of a temperature control trap when the valve is first opened and the condensate temperature

The temperature difference (⊿t) when the air initially flows through is large and indicates that the flow rate also increases.

* Curve1 shows the maximum capacity of the trap when discharging cold condensate.

**Curve2 shows the maximum capacity of the trap when discharging hot condensate at a temperature of 10 C (18 F) below the set temperature of the trap.