Steam trap G15N

- Suitable for condensate recovery

- Horizontal installation

- Automatic venting

-

No condensate build-up on the primary side (float system with continuous drainage)

The float mechanism drains the condensate immediately and at saturation temperature, preventing the condensate from accumulating on the primary side. Ideal for applications where condensate must not be allowed to build up.

-

Compact with high discharge capacity

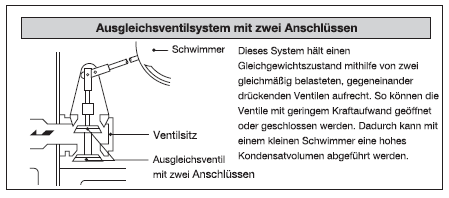

An equalizing valve with two connections (duplex) ensures high drainage capacity with compact dimensions. Thanks to its conical shape, this valve offers maximum tightness and a high flow volume.

-

Easy maintenance

This model can also be repaired built-in and is therefore quick and easy to maintain.

-

Condensate recovery

With its high back pressure tolerance, this model is suitable for condensate return.

-

No vapor or air entrapment

The membrane capsule deaerator ensures fast commissioning. Venting is based on the saturation temperature and prevents air and steam congestion.

Typical applications

Suitable for use in various process applications such as large heat exchangers in various industries, e.g. industrial plants, food processing equipment, dyeing/cleaning equipment and air conditioning systems.

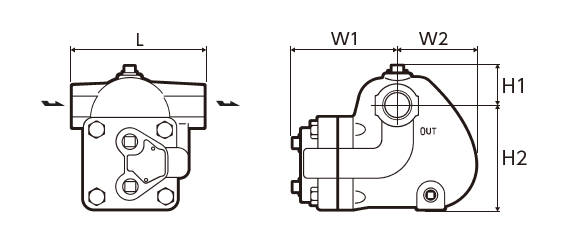

| Nominal width | Dimensions (mm) | Weight (kg) | ||||

|---|---|---|---|---|---|---|

| L | H1 | H2 | W1 | W2 | ||

| 1 1/4″ | 300 | 130 | 90 | 30 | 230 | 20,0 |

| 1 1/2″ | ||||||

| 2″ | ||||||

* Screw flange and customized dimensions on request.

| Model | Connection | Max. Operating pressure (bar) | Max. Differential pressure (bar) | Max. Operating temperature (℃) | Housing material | |

|---|---|---|---|---|---|---|

| Type | Nominal size | |||||

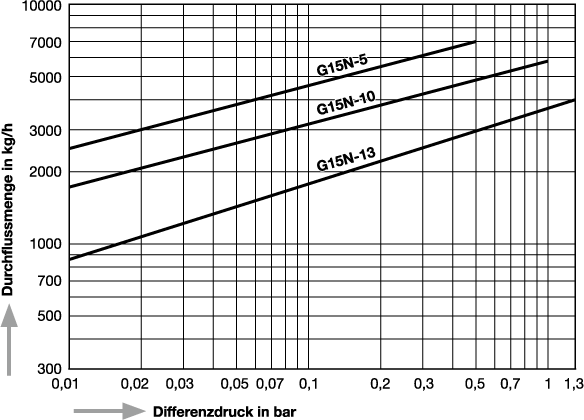

| G15N-5 | Flange FF, RF | 1 1/4″ | 5 | 5 | 220 | Gray cast iron FC250 |

| 1 1/2″ | ||||||

| 2″ | ||||||

| G15N-10 | 1 1/4″ | 10 | 10 | |||

| 1 1/2″ | ||||||

| 2″ | ||||||

| G15N-13*1 | 1 1/4″ | 13 | 13 | |||

| 1 1/2″ | ||||||

| 2″ | ||||||