Steam trap GC1V / stainless steel

- Stainless steel

- Suitable for condensate recovery

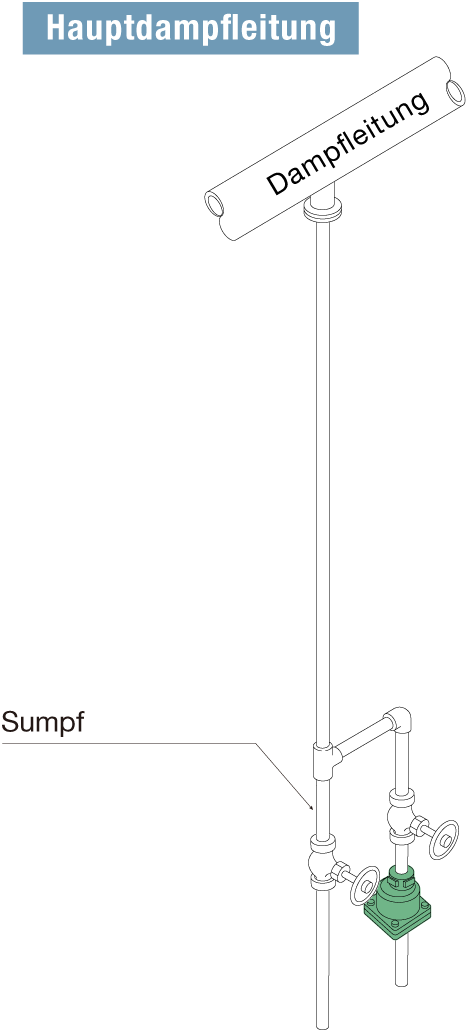

- Vertical installation

- Automatic venting

-

- Option

- – Customized flange

- – ASTM material available

-

No condensate build-up on the primary side (continuous condensate drainage due to self-regulated valve opening)

The float mechanism drains the condensate immediately and at saturation temperature, preventing the condensate from accumulating on the primary side. Ideal for applications where condensate must not be allowed to build up.

-

Outstanding sealing performance

Achieves high sealing performance and reduces steam loss thanks to a precision-polished float. The float is specially manufactured to meet the highest requirements for shape accuracy and surface tolerance. In combination with the specially lapped valve, MIYAWAKI offers one of the tightest free-floating ball steam trap designs on the market.

-

Automatic venting (due to built-in bimetal)

Compact design

-

Compact design

The lever-free design consists of fewer components and therefore reduces the risk of defects and the associated maintenance and inspection costs.

-

Stainless steel

With the exception of the bimetal, all components are made of corrosion-resistant stainless steel, which is also highly resistant to contact with aggressive steam additives.

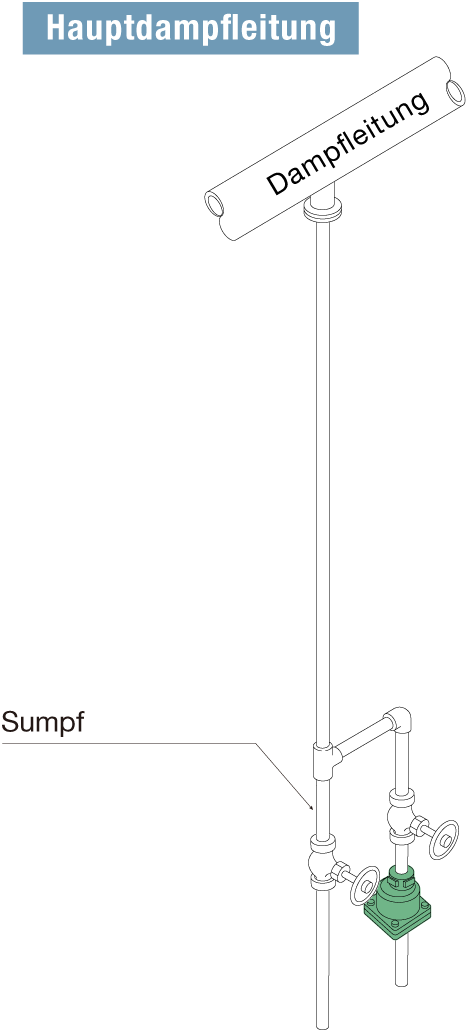

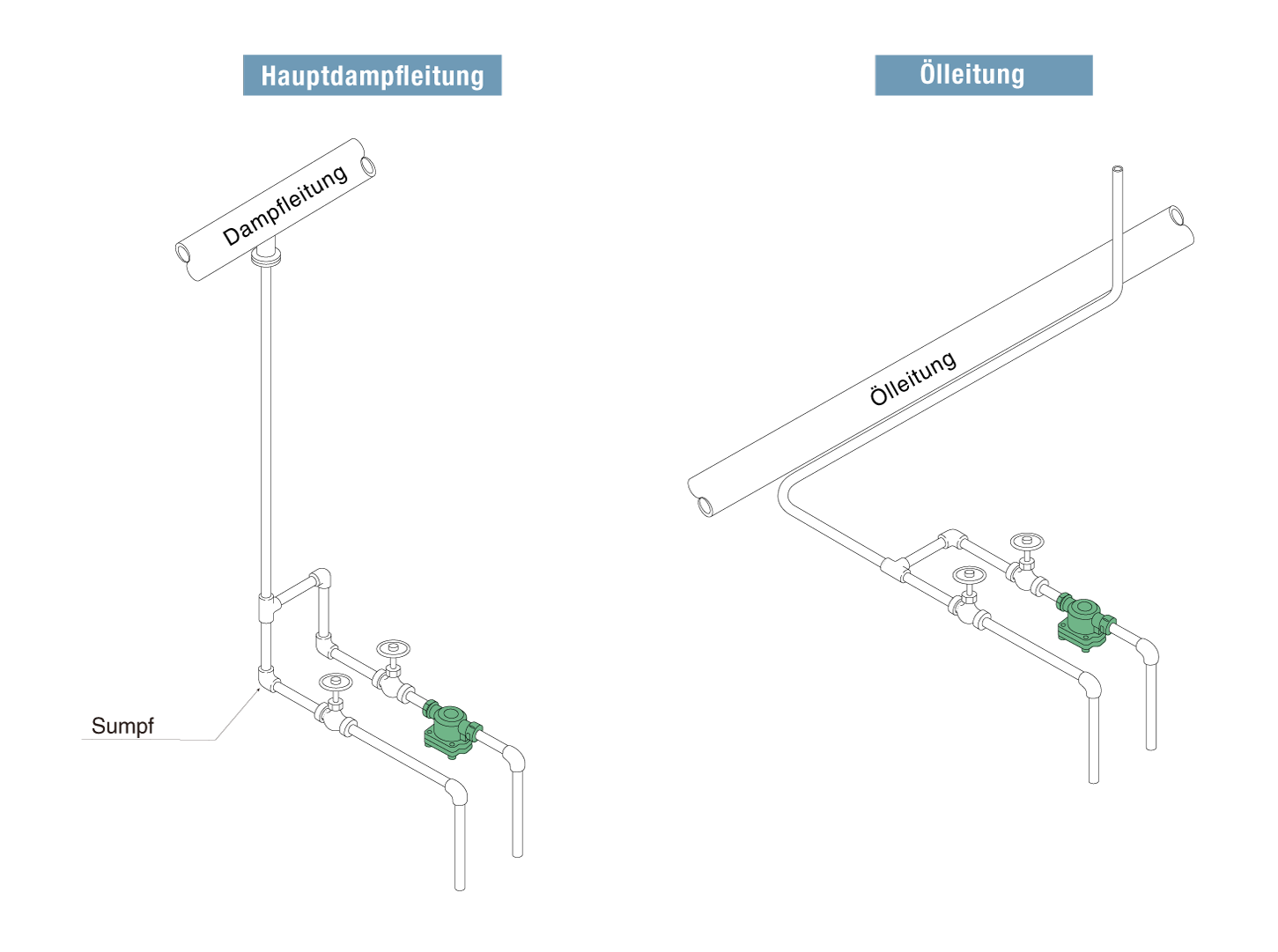

Typical applications

Suitable for steam main lines, steam tracing and other similar applications.

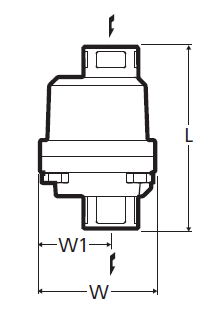

Threaded sleeve

| Nominal width | Dimensions (mm) | Weight | ||

|---|---|---|---|---|

| L | W | W1 | (kg) | |

| 1/2″ | 127 | 86 | 53 | 1,8 |

| 3/4″ | 136 | 1,9 | ||

| 1″ | 140 | 51 | 2,0 | |

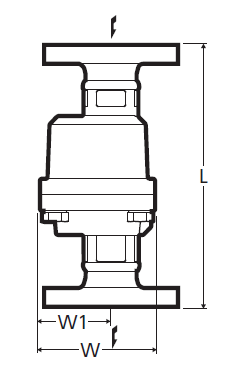

Flange

| Nominal width | Dimensions (mm) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| L | W | W1 | ASME/JPI 150lb | ASME/JPI 300lb | DIN PN40 | JIS FF | JIS RF | |

| 1/2″ | 175 | 86 | 53 | 2,9 | 3,3 | 3,3 | 3,3 | 3,5 |

| 3/4″ | 195 | 3,5 | 4,5 | 4,5 | 3,8 | 4,0 | ||

| 1″ | 215 | 4,2 | 5,3 | 5,3 | 5,0 | 5,3 | ||

* Customized dimensions on request.

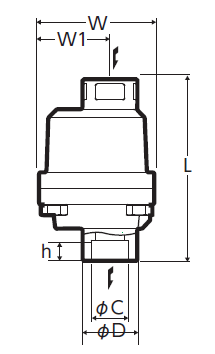

Welding socket

| Nominal width | Dimensions (mm) | Weight | |||||

|---|---|---|---|---|---|---|---|

| L | W | W1 | D | C | h | (kg) | |

| 1/2″ | 127 | 86 | 53 | 36 | 22,2 | 15 | 1,8 |

| 3/4″ | 136 | 41 | 27,7 | 1,9 | |||

| 1″ | 140 | 51 | 50 | 34,5 | 2,0 | ||

| Model | Connection | Max. operating pressure | Max. differential pressure | Max. Operating temperature (℃) | Housing material | |

| Type | Nominal diameter | (bar) | (bar) | (℃) | ||

| GC1V-10 | Threaded socket Rc, NPT |

1/2″ | 10 | 10 | 350 | Cast stainless steel SCS13A/CF8 |

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-16 | 1/2″ | 16 | 16 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-21 | 1/2″ | 21 | 21 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-10F | Flange FF, RF |

1/2″ | 10 | 10 | ||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-16F | 1/2″ | 16 | 16 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-21F | 1/2″ | 21 | 21 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-10W | Welding socket SM |

1/2″ | 10 | 10 | ||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-16W | 1/2″ | 16 | 16 | |||

| 3/4″ | ||||||

| 1″ | ||||||

| GC1V-21W | 1/2″ | 21 | 21 | |||

| 3/4″ | ||||||

| 1″ | ||||||

● Max. permissible pressure (PMA): 21 bar PMA is the design pressure of pressure-resistant parts (housing).

● Max. permissible temperature (TMA): 350 ℃ TMA is the design temperature of pressure-resistant parts (housing).

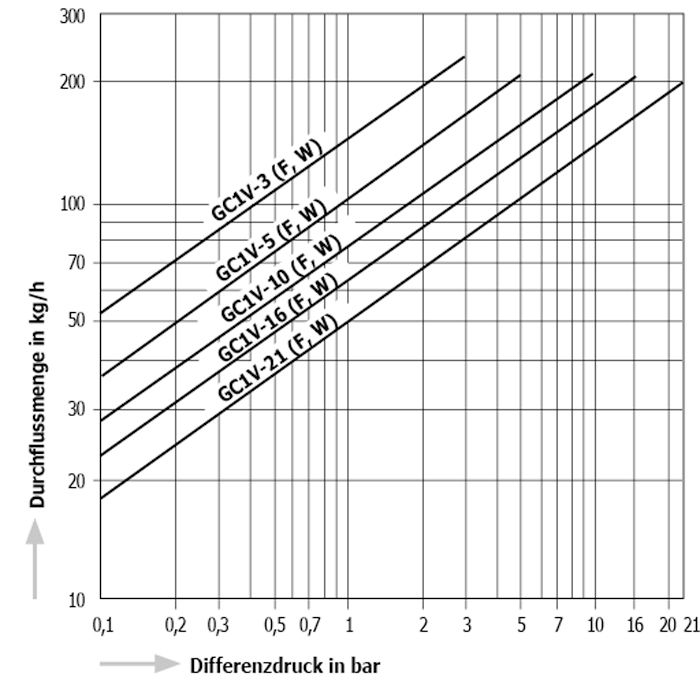

● Min. operating differential pressure (⊿PMN): 0.1 bar ⊿PMN is the minimum operating differential pressure between the inlet and outlet of the condensate drain.

* Available flange standards: ASME/JPI, DIN, JIS

GC1 Horizontal installation

GC1 Vertical installation