Steam trap GH40

- Suitable for condensate recovery

- Horizontal installation

- Automatic venting

-

- option

- – ASTM material available

-

Fast commissioning

Discharges cold air and cold condensate automatically.

-

Suitable for steam processes with medium to high volumes

Independent adjustment of the valve opening degree to the amount of condensate to maximize the heat exchange capacity.

-

Condensate recovery

With its high back pressure tolerance, this model is suitable for condensate return.

-

Easy maintenance

This model can also be repaired built-in and is therefore quick and easy to maintain.

-

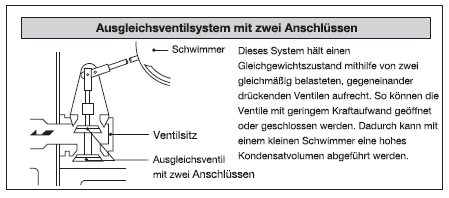

High discharge capacity

An equalizing valve with two valve openings offers a high flow capacity compared to models with only one opening.

Typical applications

Suitable for use in industrial plants, food processing plants and dyeing/cleaning equipment.

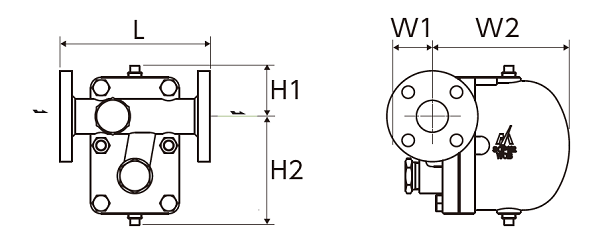

Flange

| Nominal width | Flange standards | Dimensions (mm) | Weight | |||||

|---|---|---|---|---|---|---|---|---|

| L | H1 | H2 | W1 | W2 | (kg) | |||

| 1 1/2″ | ASME/JPI | 150lb 300lb |

230 | 80 | 170 | 60 | 210 | 24,0 |

| 600lb | 240 | 27,0 | ||||||

| DIN | PN40 | 230 | 24,0 | |||||

| JIS (FF,RF) | 10K,16K,20K | |||||||

| JIS (RF) | 30K | 27,0 | ||||||

| 40K | 240 | |||||||

| 2″ | ASME/JPI | 150lb 300lb |

230 | 24,0 | ||||

| 600lb | 270 | 27,0 | ||||||

| DIN | PN40 | 230 | 24,0 | |||||

| JIS (FF,RF) | 10K,16K,20K | |||||||

| JIS (RF) | 30K | 240 | 27,0 | |||||

| 40K | 250 | |||||||

* Available flange standards: ASME/JPI 150lb, 300lb, 600lb, DIN PN40, JIS 10K, 16K, 20K, 30K, 40K

* Customized dimensions on request.

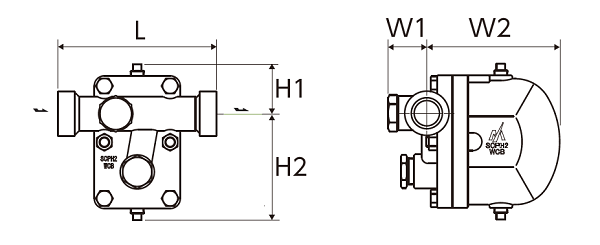

Welding socket

| Nominal width | Dimensions (mm) | Weight | ||||

|---|---|---|---|---|---|---|

| L | H1 | H2 | W1 | W2 | (kg) | |

| 1 1/2″ | 250 | 80 | 170 | 60 | 210 | 19,0 |

| 2″ | 260 | |||||

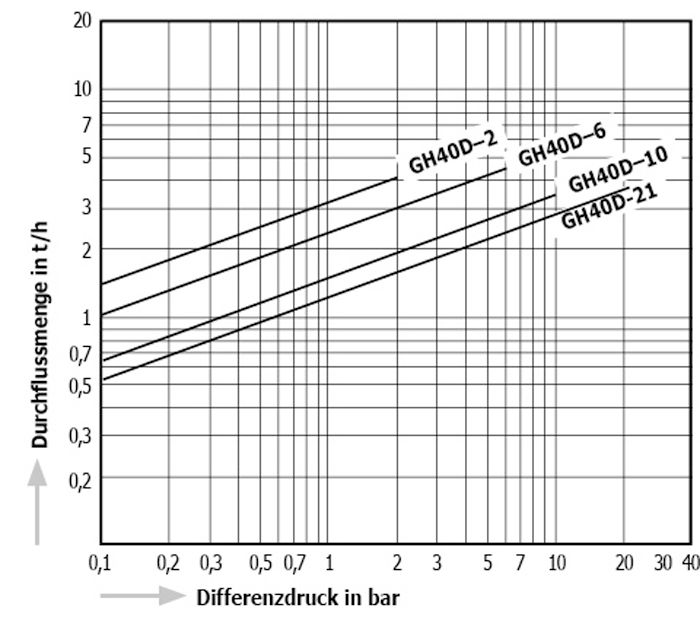

| Model | Connection | Max. Operating pressure |

Max. differential pressure | Max. Operating temperature |

Venting type | Housing material | |

| Type | Nominal diameter | (bar) | (bar) | (℃) | |||

| GH40-2F | Flange FF, RF* | 1 1/2″ | 2 | 2 | 400 | Bimetal | Cast steel SCPH2/WCB |

| 2″ | |||||||

| GH40-6F | 1 1/2″ | 6 | 6 | ||||

| 2″ | |||||||

| GH40-10F | 1 1/2″ | 10 | 10 | ||||

| 2″ | |||||||

| GH40-21F | 1 1/2″ | 21 | 21 | ||||

| 2″ | |||||||

| GH40-32F | 1 1/2″ | 32 | 32 | ||||

| 2″ | |||||||

| GH40-2W | Welding socket | 1 1/2″ | 2 | 2 | |||

| 2″ | |||||||

| GH40-6W | 1 1/2″ | 6 | 6 | ||||

| 2″ | |||||||

| GH40-10W | 1 1/2″ | 10 | 10 | ||||

| 2″ | |||||||

| GH40-21W | 1 1/2″ | 2,1 | 21 | ||||

| 2″ | |||||||

| GH40-32W | 1 1/2″ | 3,2 | 32 | ||||

| 2″ | |||||||

* Available flange standards: ASME/JPI 150lb, 300lb, 600lb, DIN PN40, JIS 10K, 16K, 20K, 30K, 40K

● Max. permissible pressure (PMA): 40 bar

● Max. permissible temperature (TMA): 400 ℃

● Max. Back pressure during operation (PMOB): 90 % of the pressure on the inlet side

* ASTM material (WCB) on request.

● This product uses a balancing valve system with two connections. If the actual amount of condensate is significantly less than the discharge capacity of the product, there may be a steam leak.