Wagner Service

Audit for steam networks

Conductors should be serviced regularly.

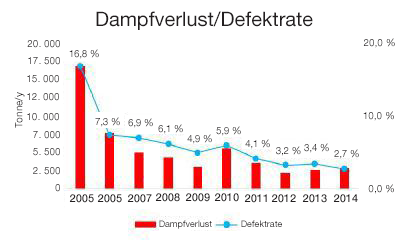

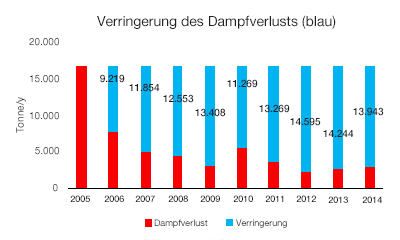

Steam traps have a limited service life. Over time, signs of wear on the valve and valve seat often lead to steam losses – and therefore to unnecessary energy consumption. Regular inspection and maintenance is therefore essential to avoid such losses. Studies show: On average, 20 to 25 % of all steam traps are defective. Wagner offers a professional inspection service that reliably reduces the failure rate to less than 5% – and saves customers energy and costs in the long term.

Minimize steam losses permanently

Regular inspection and maintenance of steam traps leads to significantly lower energy losses – and therefore to noticeable savings in operating costs.

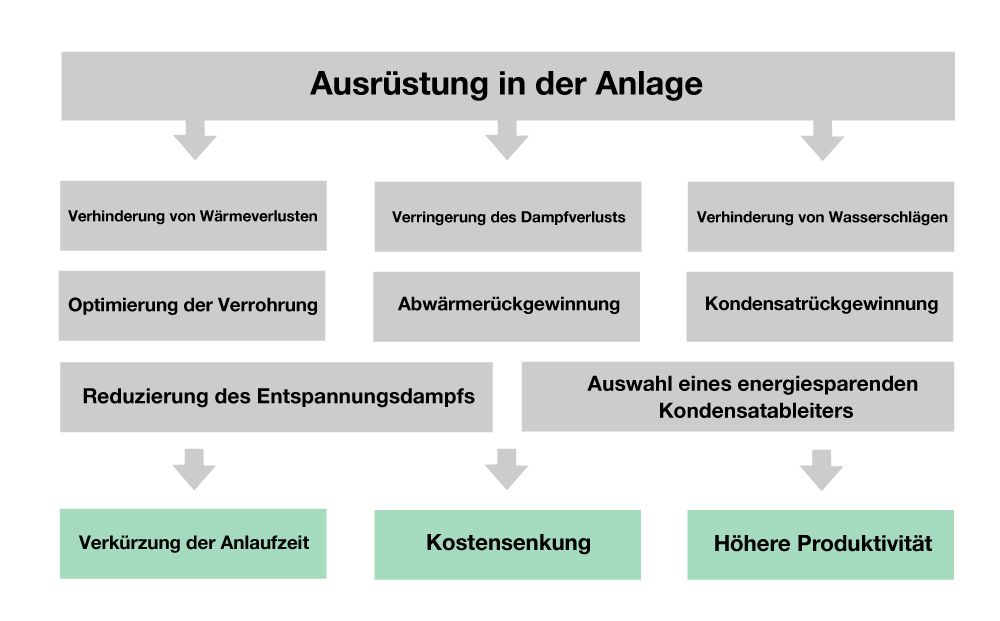

Overview of our service

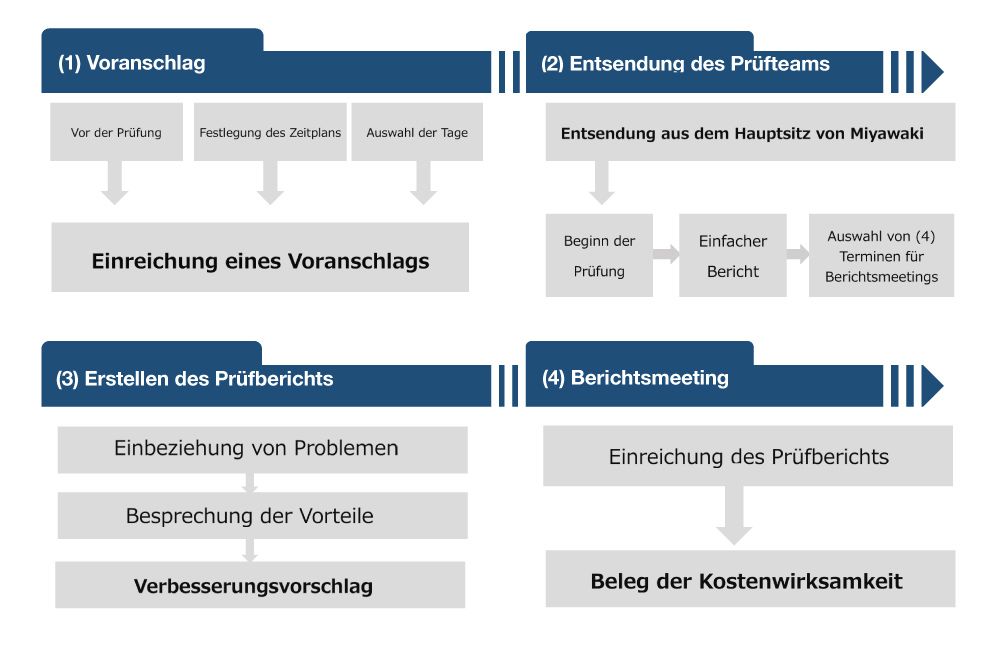

Submission of a cost estimate

Site visit

Preparation of an installation plan and a control book and affixing of control labels, etc.

Review

Checking steam traps, bypass valves and upstream and downstream valves, determining the suitability of traps, etc.

Review results report, suggestions for improvement

Summary of analysis, estimation of extent and cost of vapor loss, selection of recommended replacement products, etc.